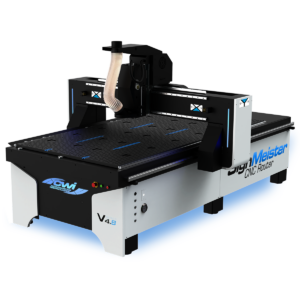

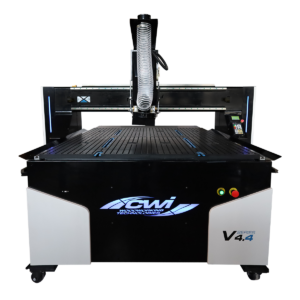

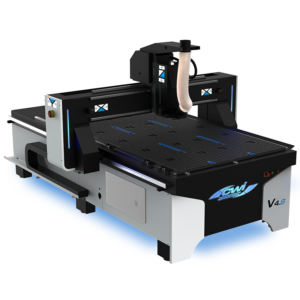

Basic 4.8 48″ X 96″ CNC Router w/HSD Italian Spindle (Version 1)

Basic 4.8 48″ X 96″ CNC Router w/HSD Italian Spindle (Version 1)

$16,999.95

This machine is in-stock and ships from our Winnipeg location.

In stock

The Basic 4.8 is perfect for advanced hobby or professional uses like sign makers and proto typing as well as educational users looking for more capacity and performance from their CNC.

The Basic series of CNC routers all start with a very heavy duty welded steel floor model frame. The black anodized aluminum table is then mounted to the steel frame for an excellent working surface with plenty of options for the use of hold down jigs. Under the frame are four heavy duty 5” diameter adjustable feet to make sure of a solid footing on the shop floor. The adjustable gantry is a full 1” thick machined aluminum frame (including the support arms as well as the cross members) which rides on very accurate THK linear guide ways. The gantry moves on 5/8” diameter precision ball screws in both “X” and “Y” movements by very good quality stepper motors. On the Basic 4.8 we use the industry leading commercial quality HSD 2.1kw (3 HP) three phase electrical spindle which comes with 1/8”, ¼”, 3/8” and ½” high precision ER25 collets. The three phase motor is then converted by a Delta phase inverter to run at 0-24,000 rpm on single phase 220 volt power. HSD is the leading Italian manufacturer of CNC spindles throughout the world. Users will find the speed, power and precision of the HSD spindle second to none. The HSD spindle motor offers 8” of “Z” travel while also utilizing a heavy duty 5/8” ball screw and stepper motor.

The machining area is just over 48” x 96” with a gantry clearance height of 8.25”. This speedy powerful machine can travel at 234“/minute and cut at up to 195“/minute. To make set up simple we include a tool measure devise for making accurate measurements of tool height when starting your projects. To operate the machine we use a NC Studio model NK105 hand held controller. Simply download your work program to a memory stick from your computer, slide it into the USB port on the control panel and the hand held controller works everything from there. A very nice feature for not only ease of operation but it keeps your computer out of the dusty world of your work shop.

The “guts” of the Basic CNC is a very elaborate control box full of Schneider CSA contactors, fuses and holders, Delta Inverter, motor controls and NC Studio control boxes. We use Omron micro limit switches for controlling stops and movements of the home positioning. The Basic 4.8 is fully CSA certified for use in Canadian and American schools and commercial applications or anywhere users need higher quality electrical protection.

The Basic 4.8 operates on 220 volt single phase power on a standard 20 amp 220 volt circuit breaker. For dust collection we include a dust boot with a 2.5” dust port to connect to standard dust hose. The Basic 4.8 ships to our customers in a wooden crate measuring 72” x 120” x 70” and weighs in at 2000 pounds.

Operating software is not included with the machine but is sold separately. Canadian Woodworker stocks and recommends the Vectric CNC products. We stock V-Carve Pro, Cut3D, Photo-Carve and Aspire. Other options you may want to consider are cutting tools and dust hose.

Configuration:

- Working Area: 48.5” X 96.5” X 8”

- 3 HP HSD Italian Industrial Air Cooled Spindle

- ER25 Precision Router Bit Collets

- 1/8”, ¼” and ½” Collets included with machine

- T-Slot Aluminum Black Anodized Table

- Gantry Clearance of 8.25”

- NC Studio NK105 Handheld Controller

- USB Information Transfer Port

- Advanced Mobile Electronics Cabinet

- Schneider Disconnect w/Safety Lockout

- Stepper Drive Motors

- DELTA Inverter

- SHIMPO Reducer

- Precision Ball Screw Z, X&Y Axis

- Traveling Speed 234”/min

- Maximum Working Speed 195”/min

- THK Linear rail

- Tool Measuring Sensor

- German Schneider Electronics

- Japanese Omron Switches

- CSA Power Supply, Switch and Contactor

- 1PH 220V 60HZ

- Plywood Crate 72″ x 120″ x 70″

- 2000 Lbs

Options:

- Vectric V-Carve Pro Software

- Vectric Cut3D Software

- Vectric Photo Carve Software

- Vectric Aspire Software

- Starter Tooling Kit