Scorpion 20″ HD Helical Thickness Planer

Scorpion 20″ HD Helical Thickness Planer

$10,899.90

The Scorpion CWI-P0720HC 20” thickness planer is a heavy built machine at an affordable value with the quality and safety features needed for any commercial environment for years of high production needs.

Scorpion jointers, thickness planers and combination machines are built by CWI Woodworking Technologies to be best in class machinery with the features, performance and quality that serious woodworkers are looking for whether in the hobby, educational or industrial woodworking industries. You will find our machines to have more cast iron, better cutters, easier adjustments, longer tables and superior quality to all competitors.

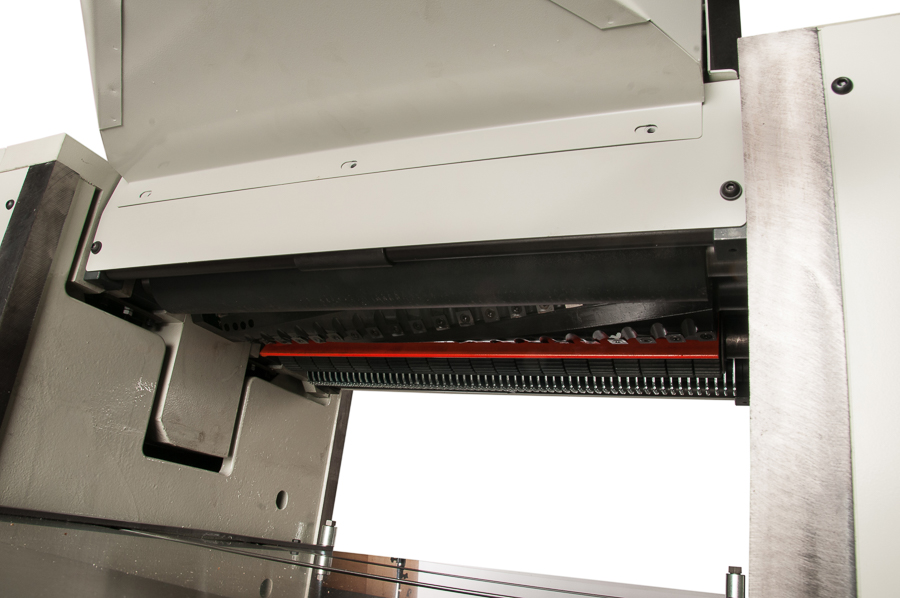

The CWI-P0720HC-M1 20” helical thickness planer is an excellent choice for educational and commercial users wanting great features with high production capacities and good safety features. The P0720HC-M1 comes standard with a single phase power 7.5 HP 220/1/60 main motor with the option of a 10 HP three phase power motor. The Stinger Carbide helical cutter head helps the machine thickness lumber at up to 1/4” at each pass with its 5 rows of 15mm x 15mm x 2.5mm square four sided convex edge carbide knives. There are a total of 100 knives used on this head. When an edge of a knife gets dull or damaged simply remove the locking screw and rotate the knife to a new edge. We find under normal wear and tear customers will get one to two years of performance from each edge of knife. The 5 rows of knives provide more knife cuts per inch, better overlap of the knives for less knife marks in the wood and virtually zero tear out even on the most difficult to thickness woods. Our Stinger Carbide helical cutter heads are renowned for ease of maintenance, quality of cut, and sound levels so pleasant you almost forget the machine is running.

The Scorpion P0720HC has two feed speeds of 22’ and 28’ per minute. There is a sectional infeed roller system to ensure a very good grip and a rubber outfeed roller. For added safety anti-kickback fingers are present in front of the sectional infeed roller.The sectional infeed roller is very importantly for safety reasons as well as a vast increase in production capabilities over a standard one piece infeed roller. Each individual section of the infeed roller adjusts for different thicknesses of wood ensuring a firm grip on each piece of wood. This allows users to put multiple boards through the machine at a time. Traditional solid steel or rubber infeed rollers will lift to the thickness of the thicker board allowing the danger of the thinner board to be ruined or worse…thrown right out of the machine.

The Scorpion precision ground cast iron table is 20” x 32” of surface area which is supported by two height adjustment columns and machined bed ways on each of the four corners of the table. On the surface of the table are two adjustable table rollers to help the feeding of rough lumber. An easy access hand lever adjustment mounted at the front of the machine is used to set the appropriate height of the rollers. The cast iron table can manually be adjusted with an oversized 8” diameter hand wheel for quick movement of the table between 3/16” and 8.25” thickness of the work piece. For extra work piece support there is an additional roller which can be engaged at the front of the table for longer lumber.

Specifications:

- 7.5 HP Main Motor 220/1/60 34 AMP (Also Available in 220/3/60)

- Magnetic Safety Switch

- 4500 RPM Cutter Head Speed

- Two Feed Speeds 22 and 28 Ft/Min

- Manual Table Elevation

- Maximum Cutting Depth ¼”

- Sectional Infeed Roller for Safety and high production

- Anti-Kick Back Fingers

- Stinger 5 Row Carbide Helical Cutter Head 3.9” dia

- 15mm x 15mm x 2.5mm carbide Knives (100 in Total) – (CWI-HCI-1 tapered knives)

- 20” x 32” Precision Ground Table

- Dual Table Rollers with Front Lever Adjustment

- Rubber Outfeed Roller

- Thickness Capacity of 3/16” to 8.25”

- Hinged Machine Hood with Protective Carpet

- Dust Hood 5”

- Floor Space 36” x 22” x 44”

- Shipping Size 42” x 38” x 50”

- Shipping Weight 1397 lbs

- CSA Certified

| Power Requirement | 10 HP 220 V Three Phase, 7.5 HP 220 V Single Phase |

|---|