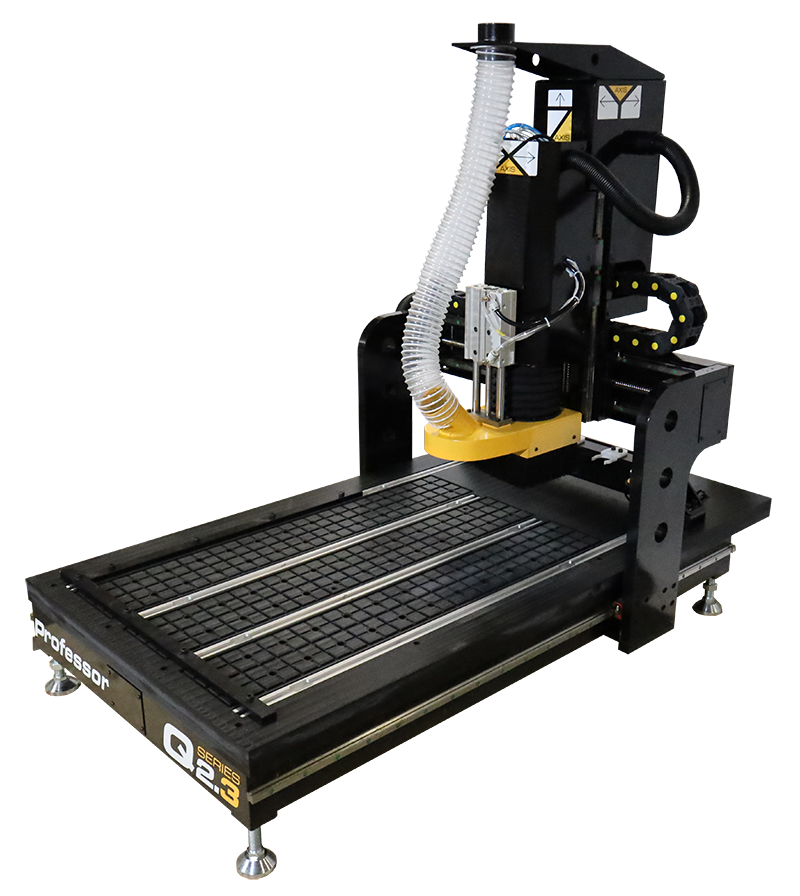

Professor Q2.3 CNC Router 24″ x 36″

Professor Q2.3 CNC Router 24″ x 36″

$15,499.95

In stock (can be backordered)

The Professor Q series of Bench Top CNC Routers are truly in a class of their own, as they feature the unique ability to automatically change up to four different cutting tools while machining a project.

Like the other Professor bench top CNC, the Q series machines are more robust, more accurate, faster, and better quality than any other bench top CNC. The Q series machines are designed by CWI for hobby, professional and educational users looking for the ultimate in CNC performance.

These advanced automatic tool change models (ATC) we call our Q series, are available in three working area sizes of 24” x 36”, 24″x 51″and 48″x48″.

The Professor bench top CNC are built solid from the ground up. The one-piece heavy-duty cast-iron frames provide a very robust structural foundation for extreme rigidity and tight tolerances. The 1” thick cast aluminum gantry and motor mounts allow a table height clearance of 8” and are propelled by exceptionally strong 4-amp stepper motors which power 5/8” heavy duty ball screws, running on THK linear guides and bearings.

The Q series machines are powered by 3.4 HP (2.5 KW) water cooled ATC router motors converted to single phase 220-volt power with use of Delta phase inverter to run at 0-18,000 rpm’s. The router spindle comes standard with 1/8”, 1/4”, 3/8” and 1/2” high precision ER20 collets with other sizes also available. Keeping the router spindle cool is a recirculating industrial chiller providing consistent clean lubrication for the spindle. Much cleaner and more efficient than a hose going to a water bucket like many competitor models.

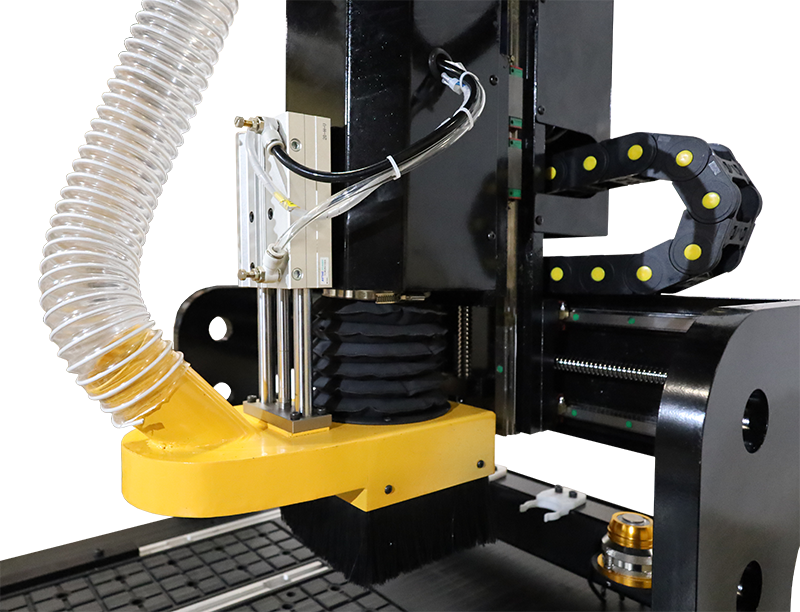

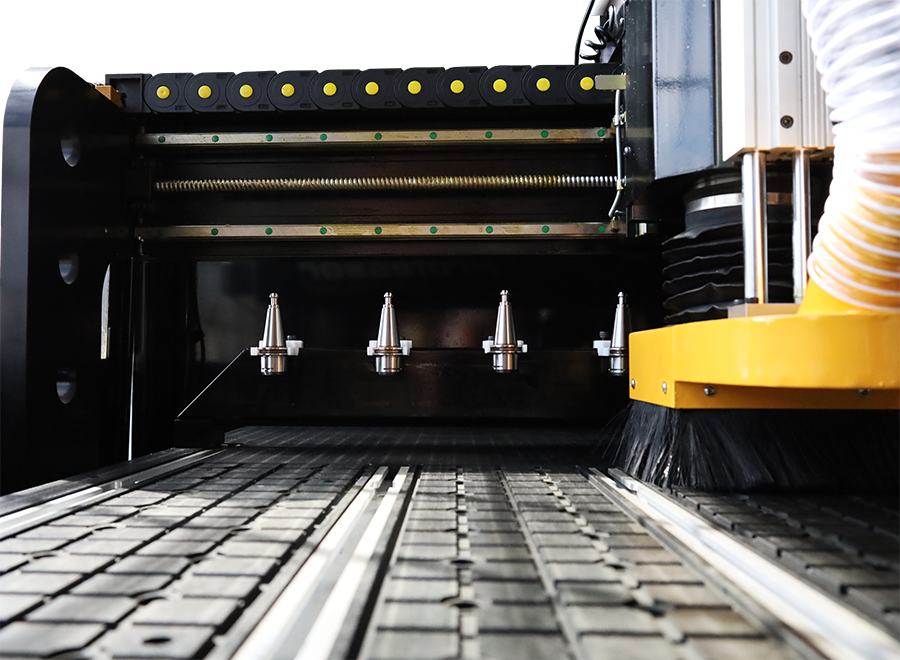

The dust collection capabilities on the Q series have been specially designed by CWI with safety, efficiency and functionality as its focus. Firstly, we designed two ports of connection. Trying to have a dust hose attached directly to the dust hood around the router spindle always creates difficulty in how to keep a flexible dust hose out of the working area. Because of this many competitor models offer a dust hood as an option and not as standard equipment. We believe dust collection to be important so adding the second port above the spindle allows a small section of dust hose to attach to the dust hood itself and the other end high above the spindle to keep the dust collector connection high out of the way. Also built into the dust hood is a dust bellows that seals the area around the router spindle down to the dust hood, creating a better enclosed suction area for increased efficiency. Then for ease of changing tooling the pneumatically controlled dust hood automatically slides up and down while changing tools. The user can also change out the tools with a simple push of a button to release the ISO25 chucks.

The working areas on the Q series CNC are dual layer Bakelite vacuum ready tables, which when partnered with an optional vacuum pump, make a great surface for vacuum clamping the work piece to the table. The tables also feature T-Slots for mechanical holding as well. This allows the user to purchase a vacuum pump with the machine or as an option in the future.

Another Unique feature of the Q series bench top CNC is the ability to add an optional fourth axis attachment for working projects in the round, up to 5” in diameter. The machines are all pre-wired, so simply purchase the fourth axis attachment and plug it into the CNC.

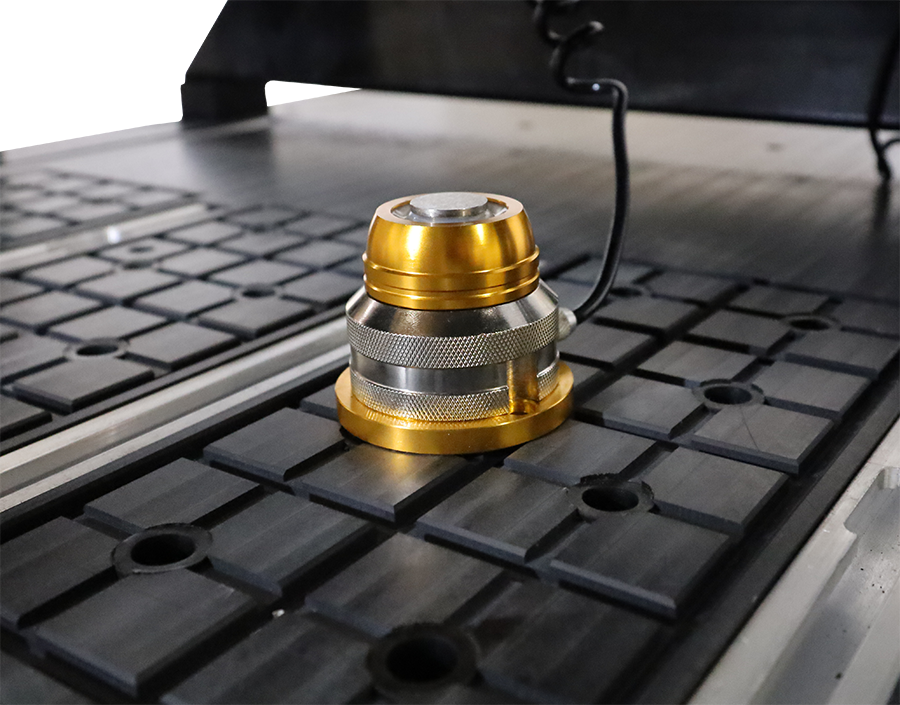

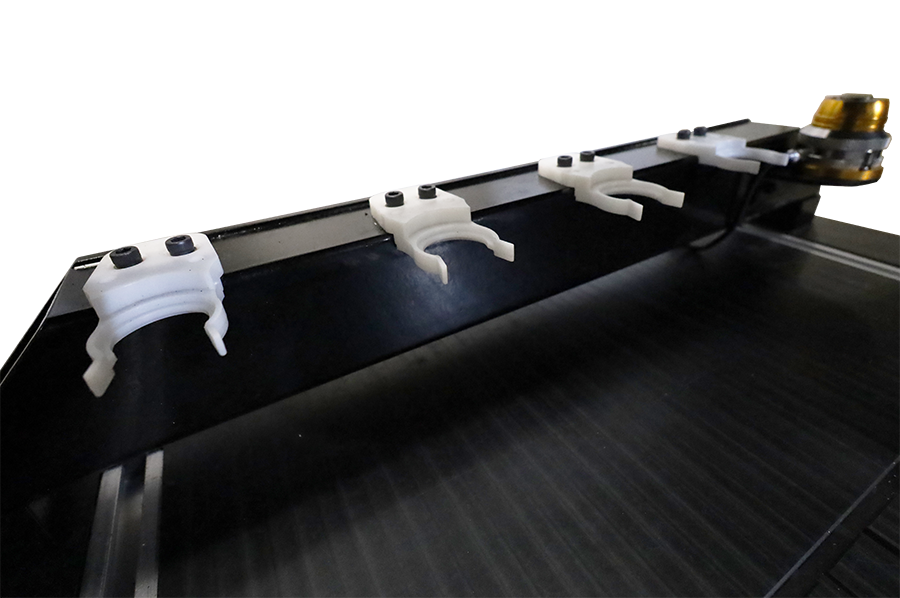

The Q series machines come standard with two tool measuring devices for making accurate measurements of cutting tool height. One measuring station is mounted directly to the tool changer bar at the back of the machine where the CNC can automatically measure and record the tool height in the ISO125 chucks. The second measuring station is portable and can be placed anywhere on the table for quick measures during project programs. The tool changer bar has 4 tool holders which can store ISO25 chucks which are supplied with the machine. The machine can then automatically, based on the program being cut, load the needed cutters to complete the project without the user having to do manual changes and tool measures.

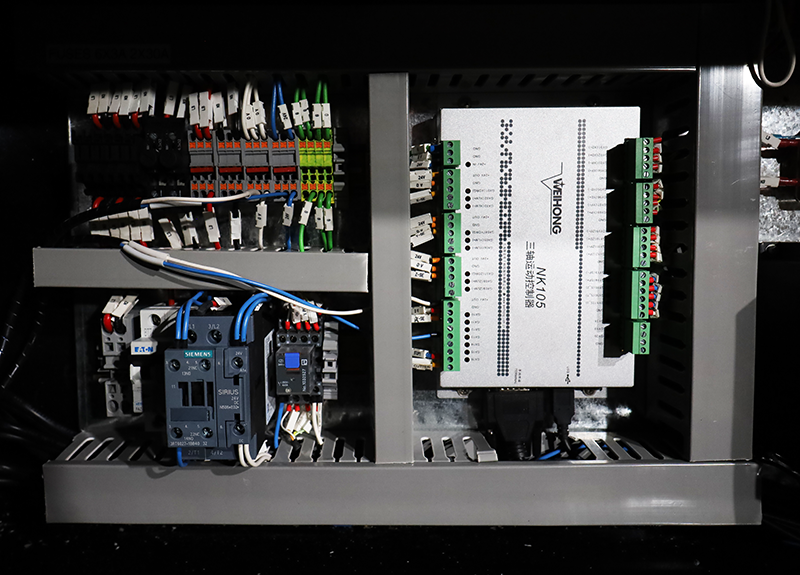

These amazing machines have a rapid travel speed of 315“/minute and can cut at up to 195“/minute. All Professor CNC feature simple to use, NC Studio model NK105 G3 handheld controllers. Simply download your work program from your computer to a memory stick, slide it into the USB port on the control panel of the CNC, and the handheld controller then loads the programs for the next projects . Using memory sticks to transfer information is important for keeping your computer out of the dusty world of your workshop.

The “guts” of the Professor is a control box full of Schneider CSA contactors, fuses and holders, motor controls and the Weihong control box. The Professor is fully CSA certified for use in Canadian and American schools and commercial applications.

The Professor Q series operate on 220-volt power and a standard 15-amp 220-volt circuit breaker.

Design software is not included with the machine but is sold separately. CWI recommends the Vectric CNC products including both V-Carve Pro and Aspire.

Other options you may wish to consider purchasing with your new Professor CNC are our newly designed heavy duty portable CNC stands and enclosures. The stands are available separately or with an additional safety enclosure. The stands feature heavy duty casters for movement around the shop as well as drawers and cabinets for storage of options like tooling, toolbox, a fourth axis attachment or a vacuum pump. The enclosures bolt down to the stands to completely enclose the operation of the CNC for safety. There are three large doors that open for ease of access to the CNC but are electronically connected to the CNC for safety. If the doors are open the CNC cannot run a project program. We offer two sizes of stands/enclosures to fit all Professor Bench Top CNC models.

Professor Bench Top CNC are the most advanced series of machines on the market today.

Model CWI-CNC2436Q

Specifications:

- Working area: 23.5” x 35.5” x 8”

- Bakelite Dual Layer Vacuum Table

- 3.4 HP (2.5 KW) ATC water cooled spindle

- 220 Volt Single Phase Power (15 amp Breaker)

- Recirculating Industrial Chiller

- Pre-Wired Fourth Axis Ready

- Four Position Tool Holder Bar

- ISO25 Tool Holders (Four Included with Machine)

- ER20 precision router bit collets

- 1/8”, 1/4” and 1/2” collets included

- Very Robust Cast Iron base frame

- Machined 1” thick aluminum gantry and support arms

- Gantry clearance of 8”

- NC Studio NK105 G3 handheld controller

- USB information transfer port

- Advanced electronics cabinet

- Stepper Class 2 Heavy Duty drive motors

- DELTA 3-phase motor inverter

- SHIMPO gear reducers

- Heavy duty 5/8” precision ball screw Z, X & Y axis

- Traveling speed 315”/minute

- Maximum working speed 195”/minute

- THK linear rails

- Dual Tool measuring stations

- Schneider CSA electronics

- Omron micro limit switches

- Advanced Pneumatically Controlled Dust Collection hood w/2.5” connection

- CSA certification

- Plywood crate

- Shipping Size: 43″ x 59″ x 50″

- Shipping Weight: 750 lbs

Options Available:

- Heavy duty steel stand with 2 tool drawers

- Deluxe Cabinet Stand with Casters and multiple Doors and Drawers for Storage.

- Metal Enclosure with Three Electrical Interlock Access Doors

- Dust Collector

- Vacuum Pump for Hold Down Work

- Fourth Axis Rotary Attachment 5” Dia

- 24″ x 51″ Working Area (CWI-CNC2451Q)

- 48″ x 48″ Working Area (CWI-CNC4848Q)

- Vectric V-Carve Pro software

- Vectric Aspire software

- Starter tooling kit

You may also like…

-

Professor CNC Deluxe Heavy Duty Steel Stand

$849.95 -

16 Piece Starter Tooling Kit for CNC Router with ER25/ER20 4HP/3.4HP Spindle

$699.95 Add to cart -

V-Carve Pro CNC Software

$959.95 Add to cart -

Professor 24″ CNC Safety Enclosure and Stand Kit

$3,599.95 -

CNC Spoilboard Cutters – 663.014.11

$109.95 Add to cart